‘Plan your work, work your plan.’ I’m a big fan of quotes like that. When I hear self-help advice like that, it stirs my mind to think something like, ‘Yes, I need to do that!’ Maybe you, too?

Alas, this blog post is NOT about self-help catch phrases. Instead, it’s about planning; HR planning. This blog asks you to think about HR planning in the context of a supply chain.

Supply chain? For people? Isn’t a supply chain what McDonalds, WalMart and Amazon have mastered and created billions in value with? Of course, but I want explore about how we can borrow some of the disciplines of the direct materials supply chain and apply these concepts to HR planning.

Stay with me for a few more minutes. We know that all the HR sub-domains plan. There is a sourcing plan. There is a recruiting plan. We have performance management plans. Most of us have compensation plans. We plan benefit offerings. Training and development are often planned out. The DEI lead has a plan. Retention and onboarding plans are common. Each HR domain has a plan. What’s missing?

You guessed it, the planning of the labor supply chain. The labor supply chain is a recent invention. David Ulrich is due most of the credit for laying out the labor supply chain; however, he didn’t call it that. He laid out the framework for a firm’s leadership to think and plan holistically for the flow of people within their firms. This Ulrich interview speaks to the reinvented HR. (I referenced Ulrich in an earlier Elevation Talent Group blog post. Ulrich’s OD work is outstanding!)

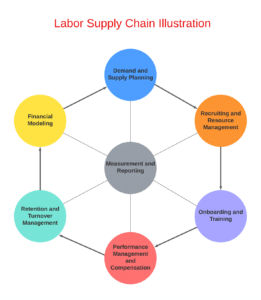

The labor supply chain is a system – a framework – with a beginning, middle and end that encompasses all the HR sub-domains. The labor supply chain has multiple inputs/output gateways that allow for comprehensive measurement systems to drive process improvement across the entire spectrum of HR processes, not just inside a siloed sub-domain. Essentially, the labor supply chain bundles HR KPIs into a system where the interactions between the HR sub-domains is defined and measured. While firms can hire brilliant leaders for the specific HR domains, firms are missing key opportunities for improvement if they fail to include lessons learned from the direct materials supply chain.

What are the goals/characteristics of a labor supply chain?

- Getting the right person to the right place at the right time. This works for the finance department and the shipping department.

- Tracking the person throughout the day and measuring performance on individual tasks. Again – not just customer service reps, but salespeople.

- Measuring the quality record of everyone. Quality of output is a consideration for every employee. Just because it’s hard to measure, doesn’t mean it doesn’t need to be.

- Providing alerts when performance falls below expectations. Consider all the KPIs and performance dashboards we use in our daily management systems. Functionally, there is very little difference between the product or service company or the production and administrative workers.

- Simulating impacts to labor because of changes to process flow or inventory. Modern business process management is all about modeling process variation on revenue, costs and quality.

- Providing visibility into cost and efficiency of individual employees, facilities, teams, and the enterprise. The CFO’s use of variable, fixed and overhead cost accounting amplifies this point.

This graphic depicts the key HR functions that compromise the labor supply chain. What is the headline? Start and end with planning and use data.

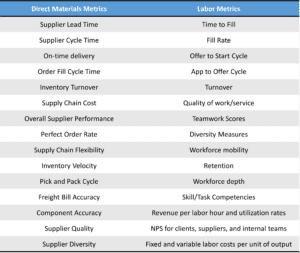

Want to dig a bit deeper? Read through this list of direct material supply chain KPIs and a labor supply chain KPIs. When considering these KPIs, a firm’s leaders will be well served to find the connectivity of each step in their labor supply chain and think through how the preceding and successive steps relate. Ask managers what their issues are. Most will blame the upstream processes and criticize the downstream processes, so understanding these friction points is essential. Analysis of the labor supply planning is as integral to a firm’s success as managing sales and marketing and production/delivery.

What do you do once you’ve thought through your HR system as a labor supply chain? Get to work improving it. Process improvement is a topic for another blog, but my go-to method is DMAIC, borrowed from the American Society for Quality training I received in the mid-1980s. Still relevant today:

- Define the problem to be solved.

- Measure – Capture the relevant data.

- Analyze your data. For example, segment your data by region, process, and manager. Identify bottlenecks and apply root cause analysis.

- Improve – design solutions that eliminate those root causes.

- Control – Monitor and track progress. Communicate and adjust strategies. Use industry trade groups to organize benchmarks.

I started this post with a classic management truism, ‘Plan your work, work your plan.’ That lesson applies to every firm, top to bottom. Companies need forward looking plans: sales and marketing, delivery/manufacturing, finance, and people (labor supply chain). Adapting the tools of the direct materials supply chain to drive improvement in HR is good advice for all of us.